We all know copper as a reddish orange metal that is gotten from the bowels of the earth; when it is in its purest form you have a malleable and soft metal that makes it one of the most accessible and useful materials whether you are thinking about making traditional tools some of the most modern applications. Copper has been used by mankind in many civilizations and for thousands of years it was used for making items ranging from jewelry all the way to work tools and other forms of artistic sculptures and kitchen cutlery; these days there are NADCAP metal finishing services that employ copper for its many advantages.

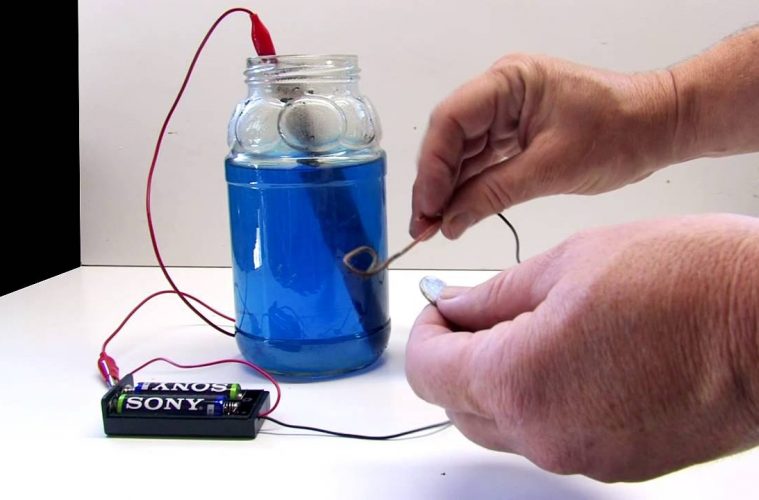

Copper plating services these days include but are not limited to copper electroplating which involves a highly refined process that is depended upon by a number of industries. One of the best advantages of copper is the fact that it has among the best conductive properties in addition to excellent thermal properties; this makes it an extremely useful substance in several processes that include electrical, industrial and heating applications. Copper plating services are used in many occasions to improve the corrosive resistance of other materials.

There are also other important applications of copper plating services such as when it used as an undercoat in several situations such as where there is a need for increased adhesion for different coatings in other materials as the need may be because it has the ability of providing a uniform coverage that is super smooth. Copper plating services are also important when they are used during the preparation of different surfaces that are meant to be soldered; most importantly copper plating services are used for other industries such as the electronics and the aerospace industry where copper plating may be required on different kinds of plastic applications.

There are other times also when copper plating services are used as a form of heat-treat stop-off during masking which allows for possible selective heat treatment as need may arise. Copper plating services are also used for many other electroplating service applications where there is a need for greater thickness and a high degree of electrical conductivity. Copper electroplating service is also normally used for during electroforming as well as during the metallization of different non-metallic materials with the best example being plastic copper plating in addition to being used on semiconductors as well as printed circuits for hole-plating.

When you think about the electroplating service, there are very many benefits that can be associated with copper plating services; because of its softness and malleability copper almost always becomes the metal of choice during different kinds of NADCAP metal finishing using flexible objects and materials. This is especially so because copper doesn’t break when it is bent.